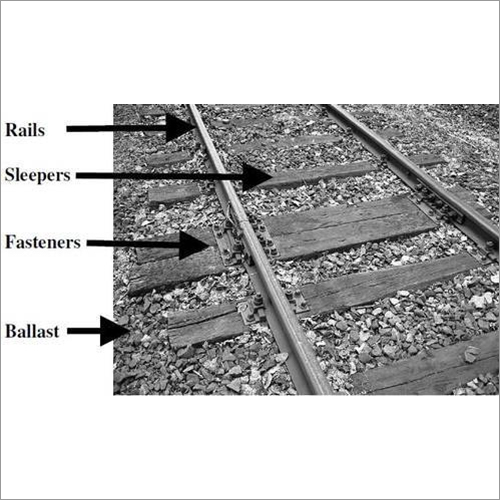

Railway Track Components

200 INR/Piece

Product Details:

- Weight Varies as per component; typically 8kg to 30kg per piece

- Technology Advanced Metallurgical Processes

- Technics Hot Forged, Precision Machined

- Color Black, Steel Grey

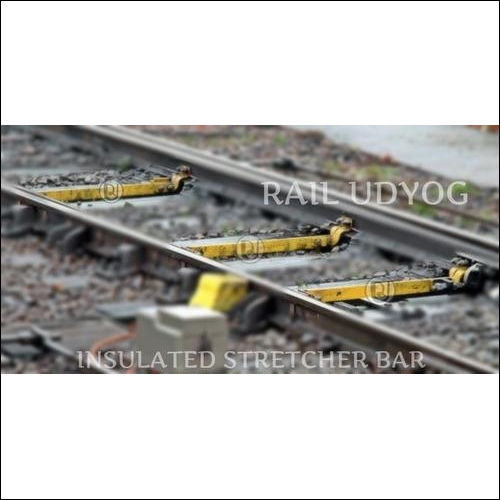

- Type Track Fittings, Rail Clips, Fasteners, Fish Plates

- Material Carbon Steel, Alloy Steel, SG Iron

- Dimensions Standard and Custom Sizes (e.g., 180mm x 120mm x 30mm)

- Click to View more

X

Railway Track Components Price And Quantity

- 1000 Piece

- 200 INR/Piece

Railway Track Components Product Specifications

- Galvanized, Painted, Plain

- Varies as per component; typically 8kg to 30kg per piece

- HB 170 to HB 350

- Track Fittings, Rail Clips, Fasteners, Fish Plates

- CNC Machining, High-Precision Molds

- Advanced Metallurgical Processes

- Hot Forged, Precision Machined

- Smooth, Anti-rust Coated

- Black, Steel Grey

- Carbon Steel, Alloy Steel, SG Iron

- Standard and Custom Sizes (e.g., 180mm x 120mm x 30mm)

Railway Track Components Trade Information

- 50 Piece Per Day

- 30 Days

Product Description

We are indulged in the production of top quality of Railway Track Components that are designed as per the latest norms that are set in the industry. Our purpose is to provide durable, strong and corrosion free items in the markets that can meet the high standard requirements of customers efficiently. These components are fabricated through high in strength material. Their dimensional perfection and accuracy are what makes them the best products in the domain. We only supply the well finished Track Components.

Rail Track Components Specifications:

- Material: Cast Iron

- Strength: Machine finished

- Finish: Powder Coated

Exceptional Strength & Durability

Our railway track components guarantee minimum tensile strength of 600 MPa and impact resistance of 13J, ensuring reliable performance under heavy loads and extreme operational conditions. They undergo rigorous testing, conforming to international rail standards, and are made with state-of-the-art forging and CNC machining for unparalleled durability.

Advanced Corrosion Protection

To maximize longevity in outdoor rail applications, components feature high corrosion resistance thanks to premium anti-rust treatments and smooth surface finishes. Options such as galvanization and painting provide extra protection, which is vital for installations across diverse climates.

Versatile Compatibility & Customization

Designed for universal compatibility, our products meet UIC, AREMA, and Indian Railways standards. Customers can choose from standard or tailor-made sizes to suit railway track assembly, heavy haul lines, and metro rail projects. Various finishes, colors, and weights are available to accommodate specific requirements.

FAQ's of Railway Track Components:

Q: How are these railway track components manufactured to ensure high tensile strength and precision?

A: Each component is produced using hot forging and advanced metallurgical techniques, followed by precision CNC machining. This process ensures a minimum tensile strength of 600 MPa and maintains strict tolerances of 0.02mm, resulting in highly reliable products.Q: What anti-rust treatments are used to achieve high corrosion resistance?

A: Components undergo specialized anti-rust coatings, such as galvanization or painting, which effectively shield against corrosion. These treatments offer excellent durability even in harsh outdoor environments and are tailored for long-term railway operations.Q: When should I consider using customized dimensions for these components?

A: Custom dimensions are ideal when your railway project has unique requirements beyond standard specifications. Our manufacturing capabilities allow us to produce sizes like 180mm x 120mm x 30mm or as needed, ensuring a tailored fit for heavy haul, metro, or specialty track assembly.Q: Where can these railway track components be used?

A: Our versatile components can be deployed in railway track assembly, heavy haul lines, and metro rail projects. They are designed to perform reliably under demanding conditions and are suitable for Indian Railways as well as international applications meeting UIC and AREMA standards.Q: What are the benefits of the high fatigue life and impact value?

A: With a fatigue life over 3 million cycles and a minimum impact value of 13J, the components offer extended service intervals and enhanced safety. This reduces maintenance needs and ensures stability under dynamic loads encountered in modern rail networks.Q: How do surface finishes improve the functionality and lifespan of these components?

A: Surface finishes-including smooth galvanization, painting, or plain treatments-protect against rust and physical wear. They also ensure better fit and operation within rail assemblies, leading to longer service life and improved performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Railway Track Fittings' category

|

RAIL UDYOG

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |