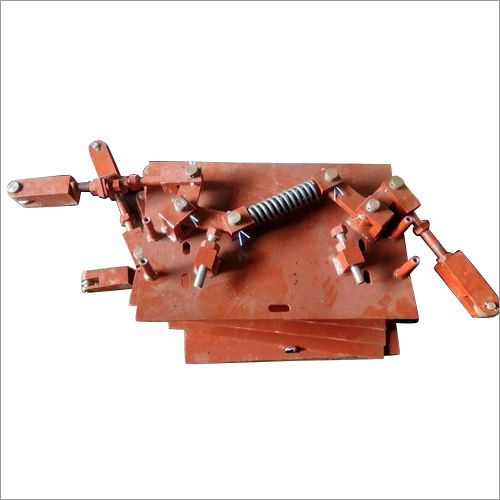

Railway Spring Setting Device

22500 INR/Set

Product Details:

- Weight Approximately 18 kg

- Color Silver Grey

- Technics Precision Machined

- Technology Manual / Mechanized

- Type Spring Setting Device

- Material High-grade Forged Steel

- Dimensions Length: 360 mm; Width: 180 mm; Height: 150 mm

- Click to View more

X

Railway Spring Setting Device Price And Quantity

- 22500 INR/Set

- 15 Sets , , Set

- 19000.00 - 27000.00 INR/Set

Railway Spring Setting Device Product Specifications

- Corrosion-resistant Coating

- Approximately 18 kg

- High-grade Forged Steel

- HRC 32-38

- Precision Machined

- Smooth, Anti-Rust

- Custom Rail Specific Adapter

- Length: 360 mm; Width: 180 mm; Height: 150 mm

- Spring Setting Device

- Silver Grey

- Manual / Mechanized

Railway Spring Setting Device Trade Information

- 50 , , Set Per Month

- 30 Days

Product Description

Railway Spring Setting Device manufactured and supplied by us is designed as per the industrial standards that make it highly demanding among our clients and praised by our customers again and again. We use superior grade material for the manufacturing that gives high sturdiness and rigidity that ultimately results in longer life and low servicing cost. Product availed by us can be delivered to our clients with a minimum order quantity of 5 sets.

Our offered Rail Spring Setting Devices are recalled and praised by the customers again and again. This is because of their superior grade features and designing. At our premises, we have installed latest machinery and equipment through which we process each item and pull out bulk volume of products on daily basis. These advanced facilities also enable us to maintain reliable quality control on the overall production process. And, meet every specified requirement of customers for our product on time.

Robust and Versatile Construction

Manufactured from high-grade forged steel and precision machined, this spring setting device is built to withstand demanding environments. Its compatibility with multiple standard rail spring types makes it a versatile choice for various railway maintenance operations.

Safety and Performance Assured

The device comes integrated with a reliable safety lock mechanism, minimizing risks during operation. Its corrosion-resistant coating, smooth surface, and anti-rust properties ensure performance remains consistent even in harsh weather conditions.

Efficient and User-Friendly Design

With an 18 kg lightweight structure and compact footprint, the device is easy to transport and handle. Manual and mechanized operation options, coupled with custom rail-specific adapters, facilitate seamless and swift spring setting with minimal maintenance required.

FAQs of Railway Spring Setting Device:

Q: How is the Railway Spring Setting Device used during track maintenance?

A: The device is utilized to accurately position and set rail springs during railway track assembly and maintenance. Operators can use it manually or employ a hydraulic mechanism, ensuring precise installation and enhanced stability of the track components.Q: What rail spring types is this device compatible with?

A: It is designed to be suitable for a variety of standard rail spring types, making it a flexible tool for diverse railway infrastructure needs across different networks.Q: When is periodic maintenance recommended for this device?

A: Although maintenance requirements are low, it is advisable to perform periodic lubrication depending on the frequency of use and exposure to environmental conditions. Routine checks help maximize operational lifespan and safety.Q: Where is this spring setting device commonly deployed?

A: This device is widely employed at railway construction sites, track maintenance workshops, and assembly yards. Its compliance with Indian Railway standards makes it particularly suitable across Indias railway network.Q: What is the process for using the device with manual or hydraulic action?

A: To operate, securely position the custom rail-specific adapter onto the rail spring, engage the device using either the manual lever or hydraulic system, and lock it in place with the built-in safety mechanism for precision and safety during the setting process.Q: What advantages does this device offer over conventional spring setting methods?

A: Its precision machining, robust build, and safety features enable faster, safer, and more reliable spring setting, reducing downtime and enhancing productivity compared to traditional manual techniques.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Railway Spares' category

|

RAIL UDYOG

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |