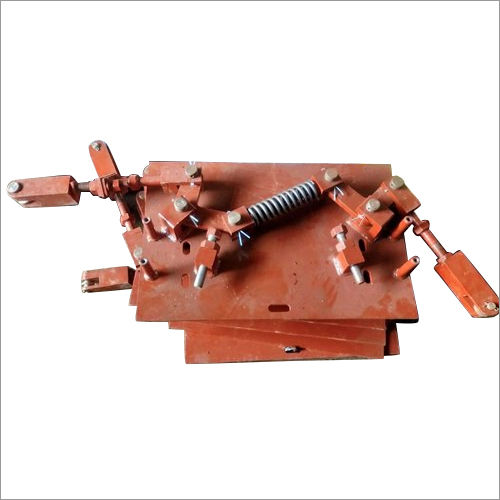

Railway Point Screw Clamp

1650 INR/Number

Product Details:

- Weight 2.5 kg (approx)

- Technics Forged

- Technology Heat Treated

- Color Black

- Type Railway Point Screw Clamp

- Material Mild Steel

- Dimensions Standard fitting for 52kg/60kg rail sections

- Click to View more

X

Railway Point Screw Clamp Price And Quantity

- 50 Piece

- 1650 INR/Number

- Standard Metric Thread

- As per Indian Railways specifications

- Wooden/HDPE bags available

- High tensile strength for secure clamping

- -20°C to +80°C

- Manual with spanner/wrench

- Low; periodic inspection recommended

- Oil dipped and oxide finish

- Used for rail track joints and fixing of rail points

Railway Point Screw Clamp Product Specifications

- Corrosion Resistant

- Black

- Mild Steel

- Standard fitting for 52kg/60kg rail sections

- 2.5 kg (approx)

- Black Oxide Coated

- Railway Point Screw Clamp

- 38-42 HRC

- Heat Treated

- Forged

- CNC Machined for precision

- Standard Metric Thread

- As per Indian Railways specifications

- Wooden/HDPE bags available

- High tensile strength for secure clamping

- -20°C to +80°C

- Manual with spanner/wrench

- Low; periodic inspection recommended

- Oil dipped and oxide finish

- Used for rail track joints and fixing of rail points

Product Description

We have enlisted ourselves as the most convenient source of Railway Point Screw Clamps in the global marketplace. At our firm, we always keep a stock of finely finished and quality assured products to meet the urgent requirements of customers within stipulated frame of time. Our ultra-advanced infrastructural facilities allow us to continuously improve the overall quality of our products and, present newer-better items to the customers from time to time. This is why, our offered Rail Point Screw Clamps hold premium spot in the markets.

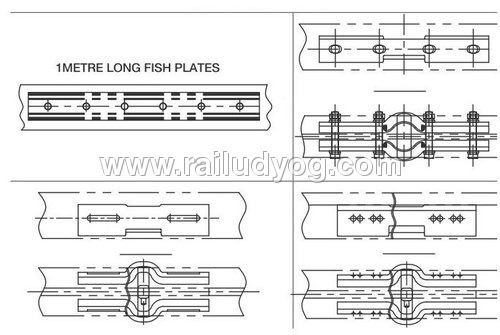

Precision in Rail Joint Security

Engineered with advanced forging and heat treatment techniques, the Railway Point Screw Clamp delivers unmatched clamping force, crucial for the stability of rail track joints. Each piece is CNC machined for dimensional accuracy, ensuring compatibility with standard 52kg and 60kg rail sections. The robust design not only enhances operational safety but also prolongs the lifespan of railway constructions.

Reliable Performance Across Climates

This screw clamp is built to withstand wide temperature variances, operating efficiently from -20C to +80C. The combination of oil-dipped and black oxide coating ensures corrosion resistance, even in demanding outdoor environments. Such features make it ideal for diverse geographies and challenging weather, maintaining secure rail junctions season after season.

FAQ's of Railway Point Screw Clamp:

Q: How is the Railway Point Screw Clamp installed on rail tracks?

A: The clamp is manually installed using a spanner or wrench. Its standard metric thread allows easy fitting, and no specialized equipment is needed, making the process straightforward for railway maintenance teams.Q: What are the primary applications of this screw clamp?

A: The screw clamp is primarily used for securing rail joints and fixing rail points, ensuring robust alignment and stability of the rails in track sections, especially those conforming to 52kg and 60kg profiles.Q: When should periodic inspections be carried out on the clamp?

A: Though the clamp requires low maintenance, it is recommended to perform periodic inspections during scheduled railway track maintenance intervals to check for wear or loosening due to operational stress.Q: Where can these clamps be used based on their operating conditions?

A: Designed for outdoor railway environments, the clamps function effectively in temperatures ranging from -20C to +80C. Their corrosion-resistant finish makes them suitable for both humid and dry climates.Q: What manufacturing standards are followed for this product?

A: Every clamp is manufactured as per Indian Railways specifications, utilizing forged mild steel, CNC machining, and heat treatment to achieve standardized precision and durability.Q: What benefits does the oil-dipped and black oxide finish provide?

A: The dual finish offers superior rust protection, reducing the likelihood of corrosion, which enhances the clamp's service life and ensures reliability under harsh operating conditions.Q: How does the high tensile strength of the clamp benefit rail joint stability?

A: High tensile strength ensures secure clamping, minimizing the risk of rail movement or separation at joints, and contributing to the overall safety and smooth operation of the railway network.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Railway Spares' category

|

RAIL UDYOG

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |